I decided to modify my home built and very customized d-bot 3D printer so that it can print high temperature filaments such as PEEK, PEKK, and Ultem.

These filaments require temperatures up to 420°C for the hotend and temperatures of 150°C for the enclosure.

This required me to replace hotend, heater, sensors, and wiring. In addition, it required me to print parts capable of withstanding temperatures of up to 150°C without glass transition. I also have to move the power supplies and arduino controller circuit from under the print bed to the side where they are not exposed to heat.

I reprinted the parts in carbon fiber polycarbonate and have slowly been getting the printer back to a usable state.

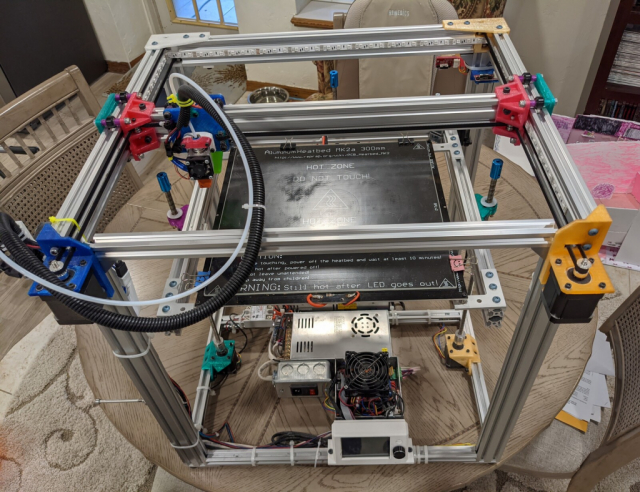

Here is what it looked like before. Most of the parts are PLA, with a few parts that need strength printed in ABS:

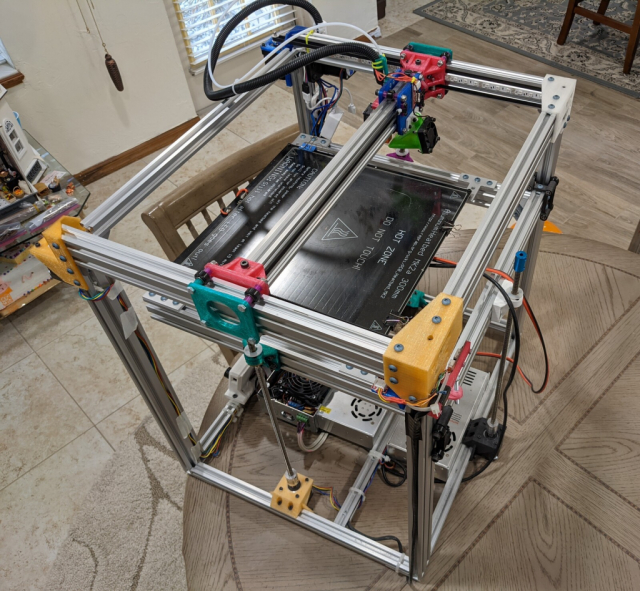

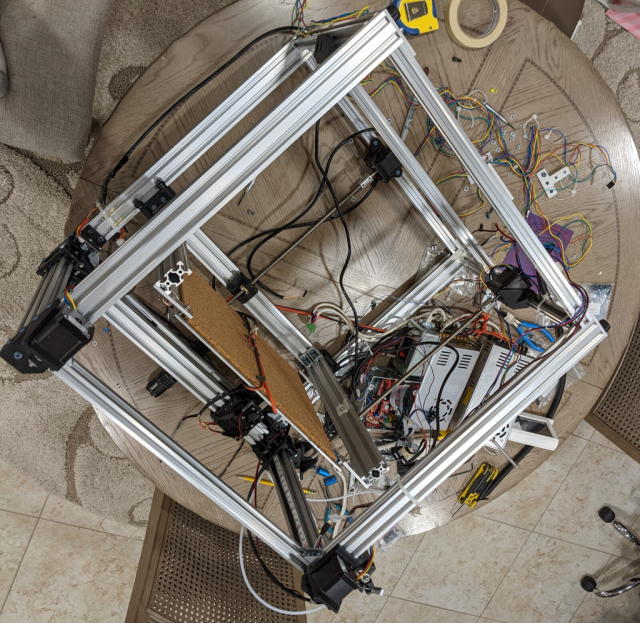

Here is the printer after replacement of parts and disassembly of electrical rigging:

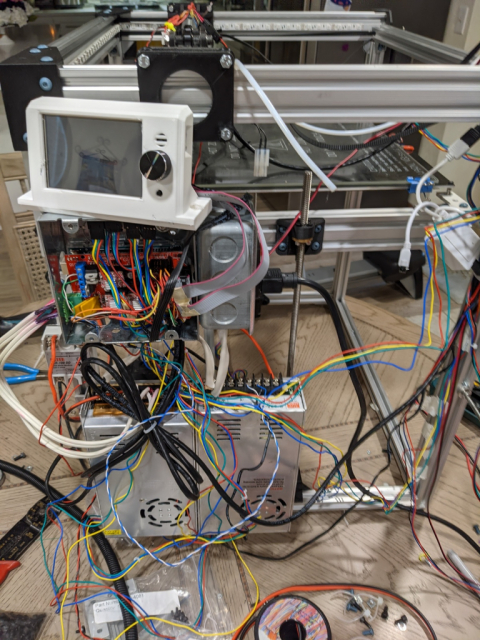

Here is the printer new power supply and controller rigging as well as testing wiring. Once all is proven, I'll tuck the wiring away so that it is nice and neat.

Once I have the wiring complete and I test drive the printer with standard filaments, I'll build the enclosure to contain the heat and perform some test prints with ABS. Then, I'll slowly ramp the heat up to temperatures that PEEK require, first with the hotend, then with the enclosure.

I'll keep you posted with my progress.